Distillation systems

Discover our precision Distillation Systems

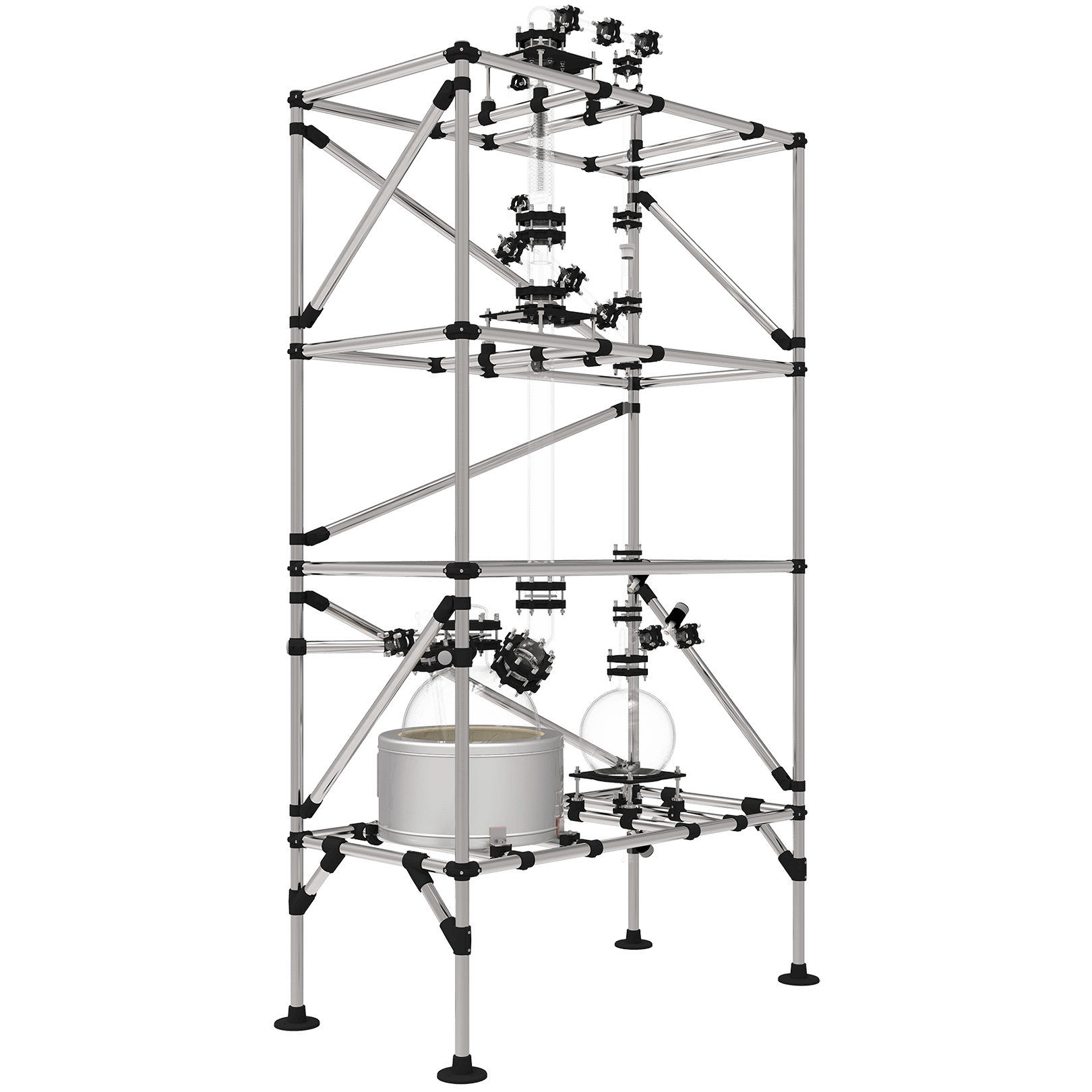

H.S. Martin designs and manufactures a wide range of lab distillation systems in both glassware and stainless steel. Distillation glassware systems range from 50 to 200 L and stainless steel systems range from 50 to 100 Gal.

H.S. Martin short path distillation units are designed to operate at atmosphere or under vacuum and are customizable to suit practically any customer’s requirements.

Read about custom lab distillation systems.

50 L, 100 L, 200 L

(spherical glass)

50 gal, 100 gal

(stainless steel)

Stirring options are available. Contact us for availability and application.

Applications across various industries

Our distillation systems are trusted by leading laboratories and industries worldwide for their precision, durability, and adaptability. Whether in research, manufacturing, or specialized fields, H.S. Martin systems excel in every environment.

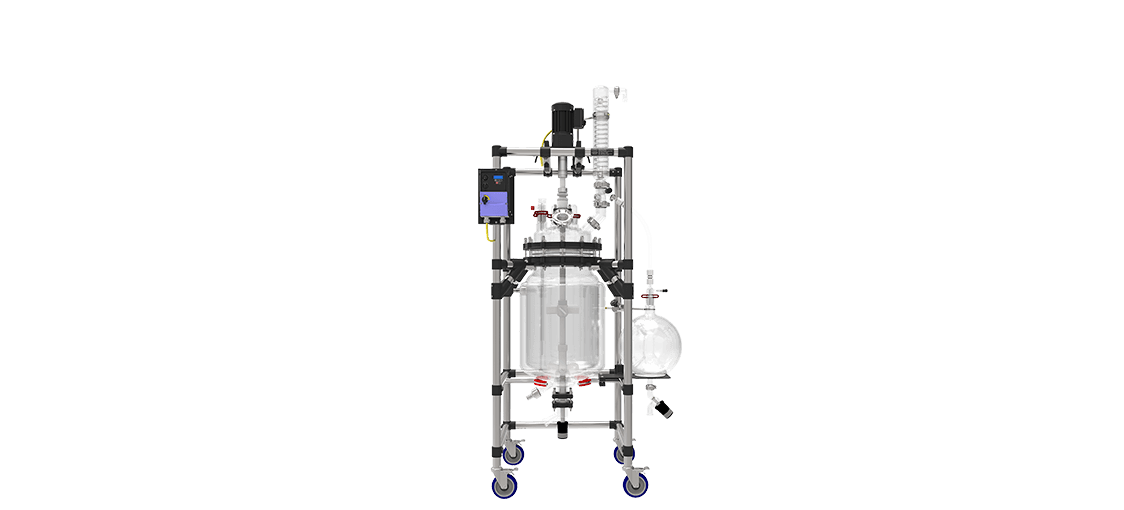

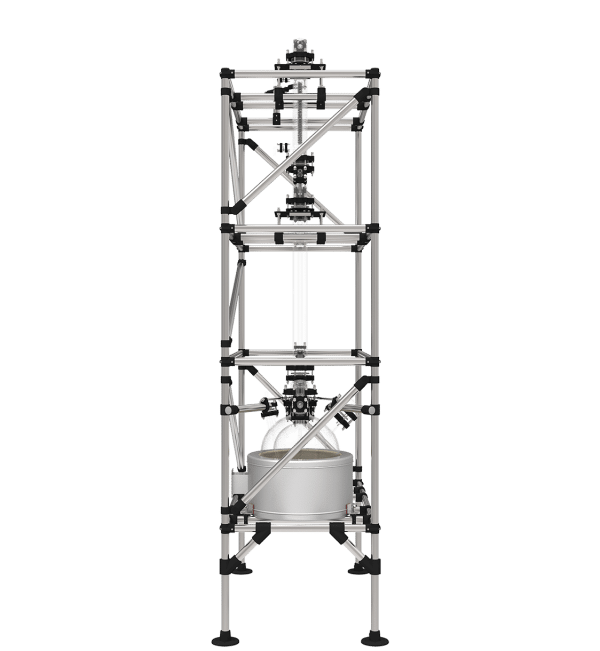

H.S. Martin 50 L Distillation System

Pressure

Up to 7 PSI (.5 Bar) to full vacuum

Temperatures

Up to +200 °C

Framework

Polished SS pipe

Material

33 expansion borosilicate glass

Wetted surfaces

Borosilicate glass or PTFE

O-ring material

FKM*

Flask heating

Via aluminum-housed bottom high-temperature 230 V mantle

Instrumentation & controls

May be provided upon request Contact us for availability

*Other compounds available on request

Explore the system

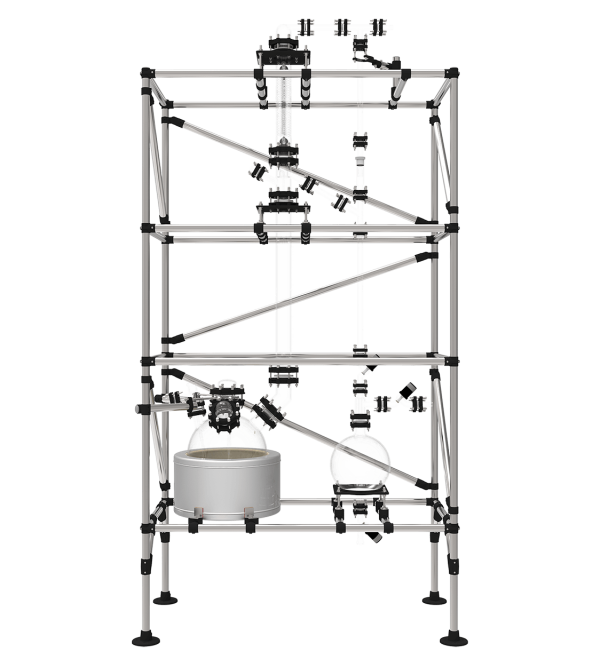

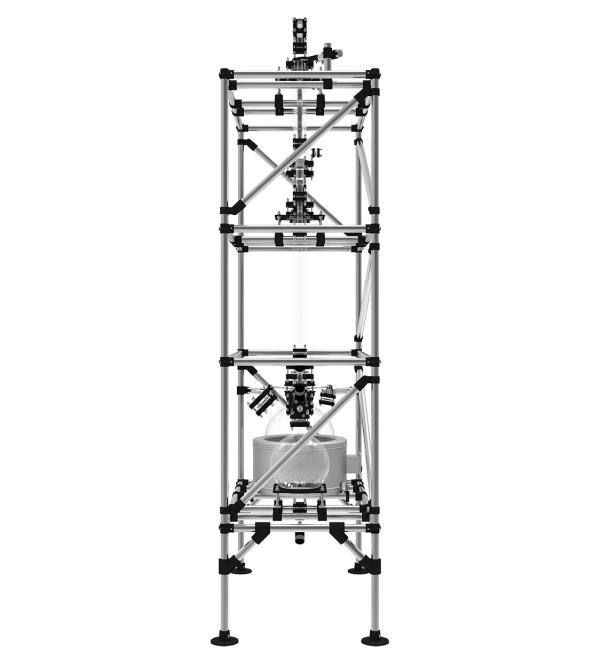

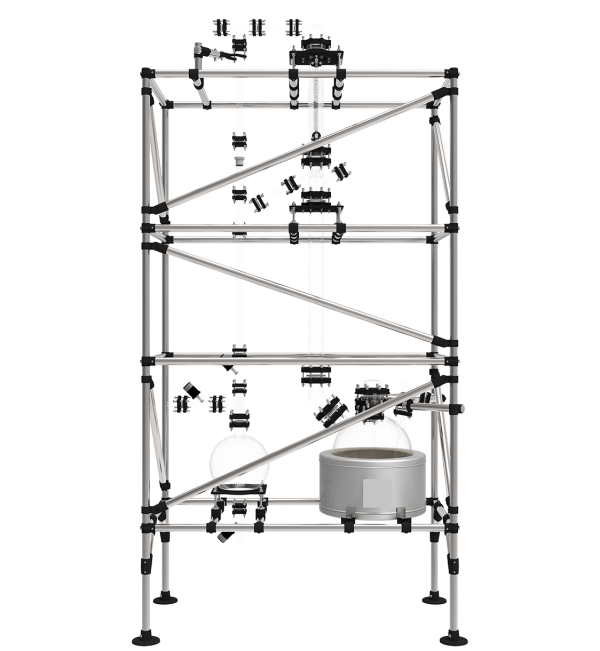

Condenser: Condensers with various heat exchange areas (HEA) are available. They are also stackable. This allows you to adjust the cooling capacity of the system to meet your specific requirements.

Added for Reflux Divider: Reflux dividers are available in different types. Manual reflux dividers allow for easy adjustment, and automatic reflux dividers permit precise reflux ratio control.

Column : Various column heights are available to enable you to set specified theoretical plate specifications. Various packing material is available depending on your chemical compatibility requirements. Different styles of packing are also available to meet your specific needs, i.e., ceramic saddle, perforated metal, Raschig rings and woven mesh to name a few.

Framework : Stainless steel frame with epoxy-coated components. Provides years of rugged, dependable service. Frames are adjustable to accommodate future modifications to the system, i.e., components are added or replaced.

Receiver Flask : Larger receiving flasks allow for longer run times and larger cuts to be taken without disrupting the process. Equipping multiple receivers allows for continuous operation as well as sampling.

Heating Mantle : Splash guards and other heating mantle accessories and options may be available. Please contact us to discuss your requirements.

A wide range of system scales

We provide standard system solutions for distillation in volumes ranging from 50 L to 100 Gal. Customized systems are also available on request.

* Available in spherical glass

** Available in stainless steel

We're here to help

We are experts in customization. If you don't find what you're looking for, or have any questions at all, just get in touch.