Glass reactors for your needs

For over 90 years, H.S. Martin has been at the forefront of designing and manufacturing innovative glassware and engineered systems. Our passion lies in not just meeting but exceeding our customers’ expectations by providing premium tailored solutions for their exact needs. When it comes to glass reactors, we understand the importance of quality, precision, and reliability. In this blog piece, we delve into the world of glass reactors, exploring their various types, applications, customization options, and the unmatched advantages of choosing H.S. Martin.

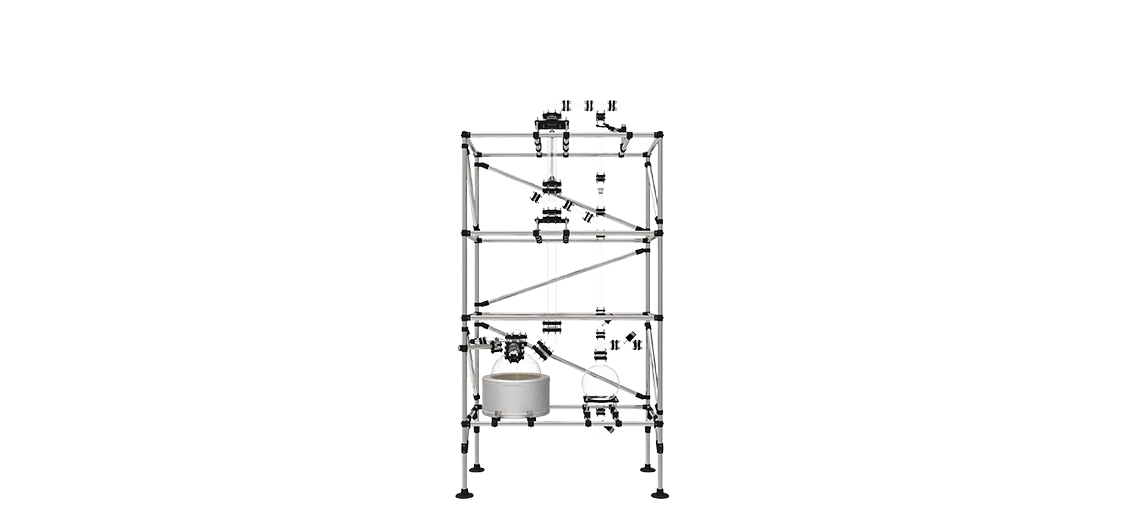

Discover our glass reactor range

At H.S. Martin, we offer a wide range of glass reactors to cater to diverse needs across industries. From laboratory-scale to industrial production, our glass reactors are designed to deliver exceptional performance and reliability. Whether you’re conducting small-scale experiments or large-scale chemical processes, our reactors are engineered to meet your requirements with precision and efficiency.

Why choose H.S. Martin's glass reactors

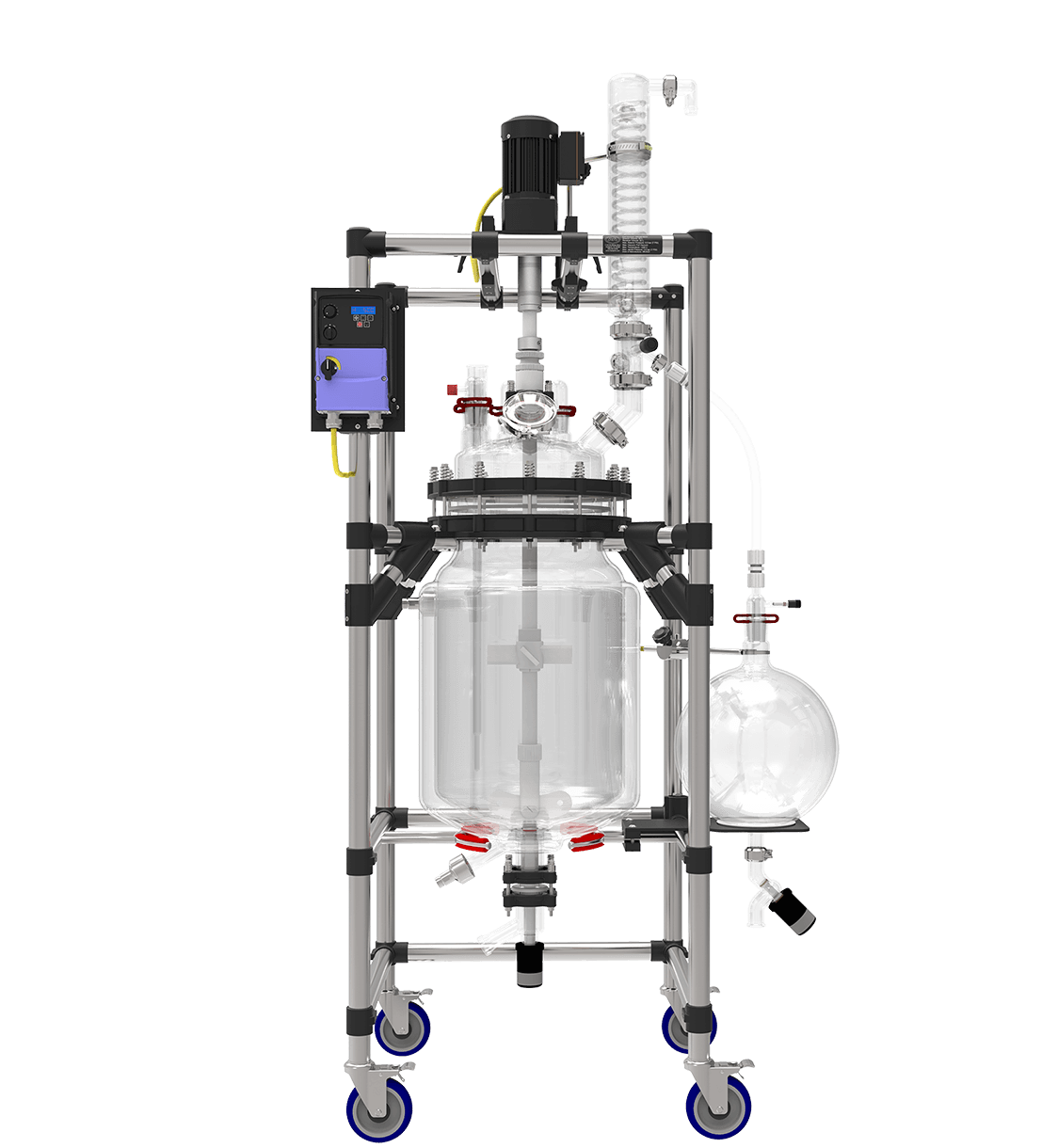

What sets H.S. Martin’s glass reactors apart is our unwavering commitment to quality, innovation, and customer satisfaction. Our reactors are meticulously crafted using high-quality borosilicate glass, ensuring excellent chemical resistance, thermal stability, and durability. With features such as jacketed or unjacketed reactors, chemical inertness, high vacuum capabilities, our glass reactors systems offer unmatched versatility and performance.

Types of glass reactors available

Our product line-up includes a variety of glass reactors, including single-layer glass reactors and jacketed glass reactors Each glass reactor is designed to suit specific applications, whether it’s chemical synthesis, distillation, filtration, or other processes. With options for customization, you can choose the reactor design that best fits your requirements, ensuring optimal results for your processes.

Customization options

At H.S. Martin, we understand that every application is unique. That’s why we offer extensive customization options to tailor our glass reactors to your specific needs. Whether it’s modifying vessel sizes, adding ports, or integrating advanced control systems, our team of experts is dedicated to creating custom solutions that enhance the efficiency and productivity of your operations.

Jacketed reaction vessels for precise control

Our jacketed glass reactors are equipped with double-layered vessels that provide precise temperature control and thermal insulation. This allows for efficient heat transfer and uniformity in temperature distribution, essential for conducting sensitive reactions and processes. Whether you’re working with controlled temperatures or vacuum environments, our jacketed reactors ensure optimal conditions for your experiments and production processes.

Applications of glass reactors

Glass reactors are used in extensive applications across various industries, including pharmaceuticals, chemicals, petrochemicals, and academia. They are used for a wide range of processes, including chemical synthesis, reaction kinetics, crystallization, and multi-step reactions. With their versatility and reliability, glass reactors play a crucial role in research, development, and production across a range of chemical applications.

Quality matters: high-quality borosilicate glass

Quality is paramount when it comes to glass reactors, and at H.S. Martin, we prioritize excellence in every aspect of our products. Our reactors are crafted from high-quality borosilicate glass, renowned for its superior chemical resistance, thermal stability, and transparency. This ensures the integrity of your processes and the safety of your operations, giving you peace of mind and confidence in your equipment.

Choosing the right glass reactor

With a plethora of options available in the glass reactor market, choosing the right one can be overwhelming. Factors such as scale, application, temperature control, and customization requirements must be carefully considered. At H.S. Martin, our team of experts is here to guide you through the selection process, offering personalized recommendations and solutions tailored to your specific needs.

Expert support at your fingertips

At H.S. Martin, our commitment to customer satisfaction extends beyond the purchase of our products. We provide comprehensive support and technical assistance to ensure that your glass reactors perform optimally throughout their lifespan. Whether you need assistance with installation, operation, maintenance, or troubleshooting, our team is always just a phone call or email away, ready to assist you with any inquiries or concerns.

Experience the H.S. Martin advantage

In choosing H.S. Martin’s glass reactors, you not only gain access to premium-quality equipment but also benefit from our decades of expertise and innovation in the field. With our commitment to quality, reliability, and customer satisfaction, we strive to be your trusted partner in laboratory and industrial processes. Experience the H.S. Martin advantage today and elevate your operations to new heights of efficiency and productivity.

Ready to explore our range of glass reactors and experience the H.S. Martin advantage? Contact us today to discuss your requirements and discover how our tailored solutions can benefit your processes and operations.