Vacuum distillation system: revolutionizing your processes

For nearly a century, H.S. Martin has been at the forefront of designing and manufacturing cutting-edge equipment, including our renowned vacuum distillation systems. Our commitment to excellence and innovation has made us a trusted partner for scientists, engineers, and educators across diverse industries.

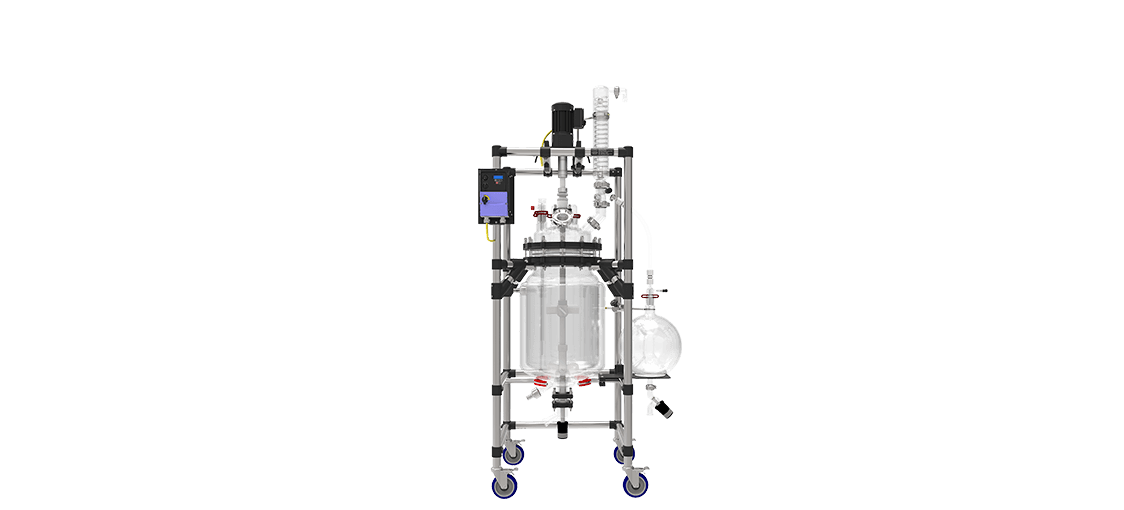

Our range of vacuum distillation systems

At H.S. Martin Glassware, we take pride in offering a comprehensive range of vacuum distillation systems tailored to meet the diverse needs of our customers. Whether you’re working with volatile compounds, refining crude oil, or involved in purification processes, our vacuum distillation units are designed to deliver unparalleled performance and reliability, minimizing energy consumption through efficient evaporation and condensation of distillate.

Our vacuum distillation systems feature state-of-the-art components including high-efficiency vacuum pumps, precision control systems, and customizable distillation columns and components. Each unit is meticulously engineered to ensure optimal performance and efficiency, allowing you to achieve precise separations even at reduced pressures. This involves using advanced evaporators and condensers for efficient phase change processes.

What is vacuum distillation?

Vacuum distillation is a sophisticated separation technique that operates under reduced pressure to lower the boiling point of the components in a liquid mixture. By subjecting the mixture to a vacuum, the vapor pressure required for boiling is reduced, allowing for distillation at lower temperatures than atmospheric distillation.

This process is particularly useful for substances with high boiling points or those prone to thermal degradation at elevated temperatures. Vacuum distillation is commonly employed in industries such as pharmaceuticals, petrochemicals, and food processing, where precise separation of components is crucial.

Benefits of vacuum distillation

The are many benefits of vacuum distillation. By operating at reduced pressures, vacuum distillation offers:

- Lower energy consumption: Reduced operating temperatures translate to lower energy requirements, resulting in cost savings and environmental benefits. This is achieved by optimizing the evaporation and condensation steps to efficiently separate the distillate at reduced atmospheric pressure.

- Enhanced product quality: By minimizing exposure to high temperatures, vacuum distillation helps preserve the integrity of heat-sensitive compounds, ensuring higher product purity and yield.

- Increased efficiency: Vacuum distillation may allow for faster distillation rates and shorter processing times compared to traditional distillation methods, leading to improved productivity and throughput.

Identifying the right type of system for your process

Choosing the right vacuum distillation system is crucial to achieving optimal results for your specific application. Factors such as the properties of the feedstock, desired product purity, and throughput requirements must be carefully considered when selecting a system.

At H.S. Martin, our team of experts is dedicated to assisting you in identifying the ideal solution for your unique needs. Whether you require a standard vacuum distillation unit or a custom system tailored to your exact specifications, we have the expertise and resources to deliver.

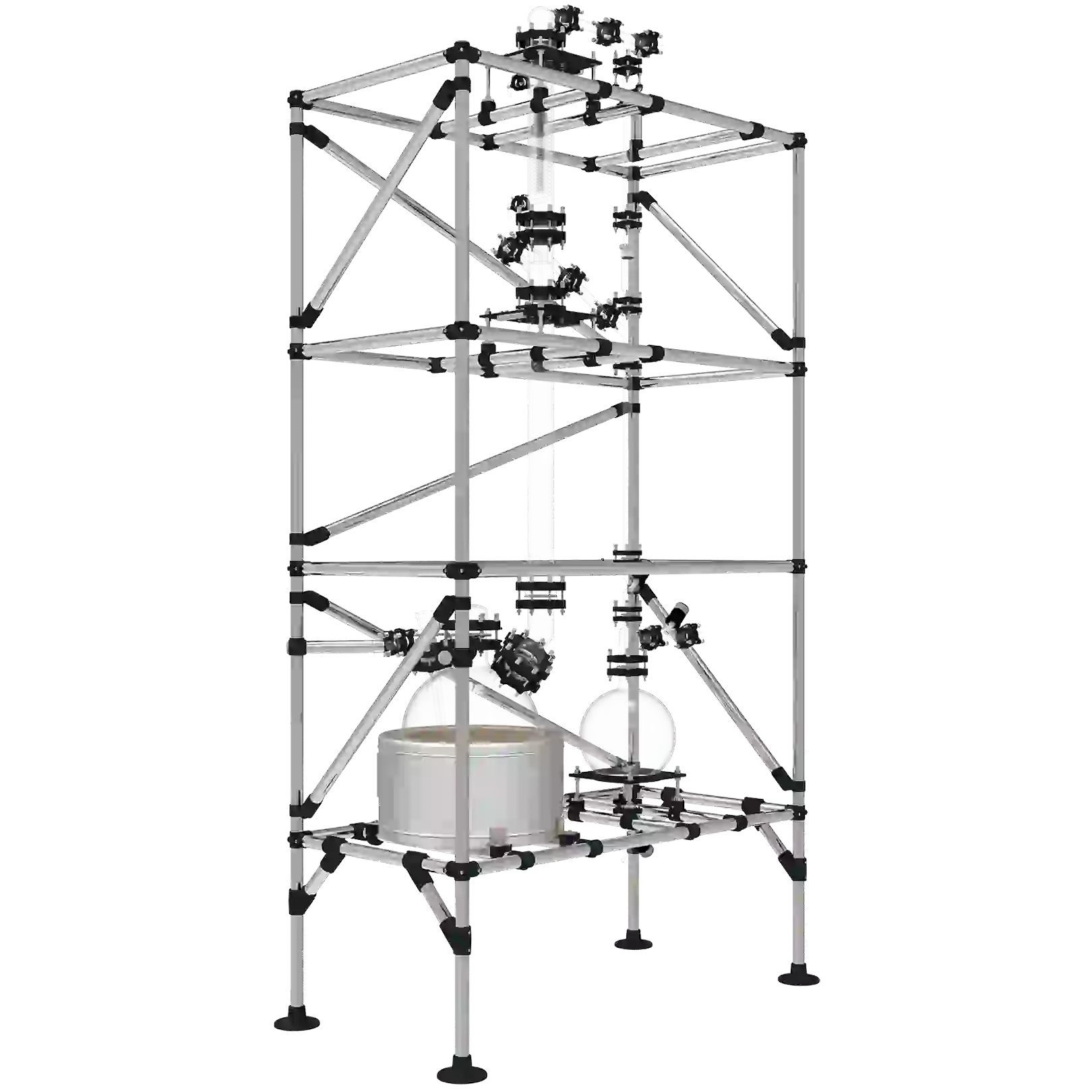

Need a custom solution?

If our standard range of vacuum distillation systems does not meet your requirements, we offer custom design and engineering services to create a solution tailored to your specific application. From molecular distillation to short path distillation, our team can design and manufacture a system that meets your specific requirements.

Contact us today to discuss your project needs and discover how H.S. Martin can revolutionize your vacuum distillation processes. With our commitment to quality, innovation, and customer satisfaction, we are your trusted partner for all your scientific glassware needs.