Custom reactors systems

For over 90 years, H.S. Martin has been a leading name in designing and manufacturing innovative glassware and engineered systems. Our commitment to excellence is unwavering, driven by our passion for providing premium, tailored solutions that precisely meet the needs of our customers. When it comes to reactor systems, we understand the intricate demands of various chemical processes and offer a comprehensive range of solutions to cater to diverse requirements.

Looking for custom reactor system specifications?

Every chemical process is unique, presenting its own set of challenges and requirements, especially in the pharmaceutical industry. Off-the-shelf solutions often fall short when it comes to accommodating specific process parameters and conditions. That’s where custom reactor systems come into play.

At H.S. Martin, we recognize the importance of flexibility and adaptability in meeting the dynamic needs of our clients. Whether it’s a specialized batch reactor system or a continuous reactor system designed for a specific chemical synthesis, we have the expertise to deliver tailored solutions that exceed expectations..

H.S. Martin range of reactor systems

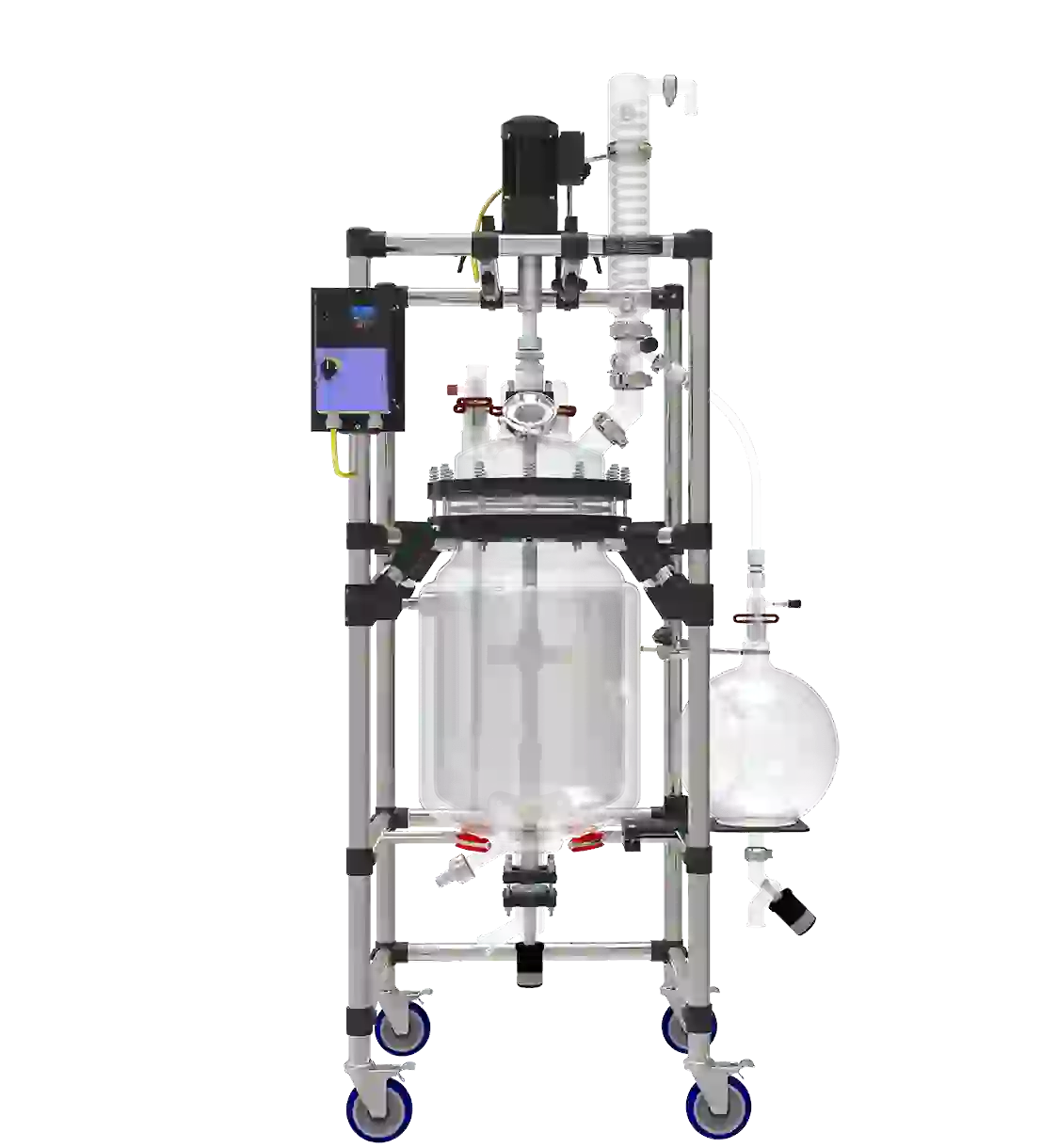

From jacketed glass reactor systems to stainless steel vessels, we offer solutions tailored to meet the diverse needs of chemical synthesis, process development, and production goals. Our reaction units offer the options of advanced temperature-programmed techniques and full access for efficient operation and control.

Whether you’re working in a laboratory setting or scaling up to pilot plants, our reactor systems are engineered to deliver consistent and reliable performance, ensuring optimal results with every use.

Why opt for custom reactor systems?

The decision to invest in custom reactor systems goes beyond convenience; it’s a strategic choice driven by practical considerations. Off-the-shelf solutions may offer a generic approach to chemical reactions, but they often lack the precision and flexibility required for complex processes.

Custom reactor systems, on the other hand, are tailored to the specific needs of your operation, allowing for greater control over reaction parameters and process optimization. Whether you’re dealing with high-pressure reactions or intricate surface area requirements, custom solutions provide the versatility and reliability needed to achieve desired outcomes.

Reasons why you should choose H.S. Martin

At H.S. Martin, we pride ourselves on our ability to deliver custom solutions that not only meet but exceed our customers’ expectations. Here are just a few compelling reasons why you should choose us for your custom reactor system needs:

- We will work directly with you to meet your exact requirements: With decades of experience in the field of chemical technology, our team possesses the knowledge and skills to design and manufacture custom reactor systems that are perfectly tailored to your requirements.

- Wide range of vessels to meet your specifications: Offering glass reactors from laboratory scale to pilot-scale production units, our comprehensive range of reactor systems suits various applications and scales of operation. Glass vessels are available from 500ml to 200l to accommodate a wide range of volume requirements.

- Commitment to quality and safety: Our systems are built to the highest standards of quality and safety, ensuring reliable performance and peace of mind for our customers.

- Customer-centric approach: Our dedication to supporting our customers has always been at the forefront of everything we do. We believe in the power of collaboration and communication. Our team works closely with clients to understand their unique needs and provide personalized solutions that address specific challenges.

- End-to-end services: From initial design concepts to final installation and support, we offer comprehensive services to ensure a seamless experience for our customers.

See our full list of capabilities to customize equipment for various industry needs here.

Contact our team today

Ready to take your chemical processes to the next level?

Contact H.S. Martin today to discuss your custom reactor system needs and discover how we can help you achieve your production goals with precision and efficiency. Experience the difference of tailored solutions designed for success.

H.S. Martin Reactor Systems

All standard H.S. Martin reactor systems are designed and manufactured with the following specifications.

Pressure

Up to 7 PSI (.5 Bar) to full vacuum

Temperatures

Up to +200 °C

Framework

Polished SS pipe

Material

33 expansion borosilicate glass

Wetted surfaces

Borosilicate glass or PTFE

Stirring power

AC electric, XP & non-XP, or air (pneumatic)

Stirrer bearings

16mm and 1-3/16”

Cover Port Configuration

As per specifications, other options are available