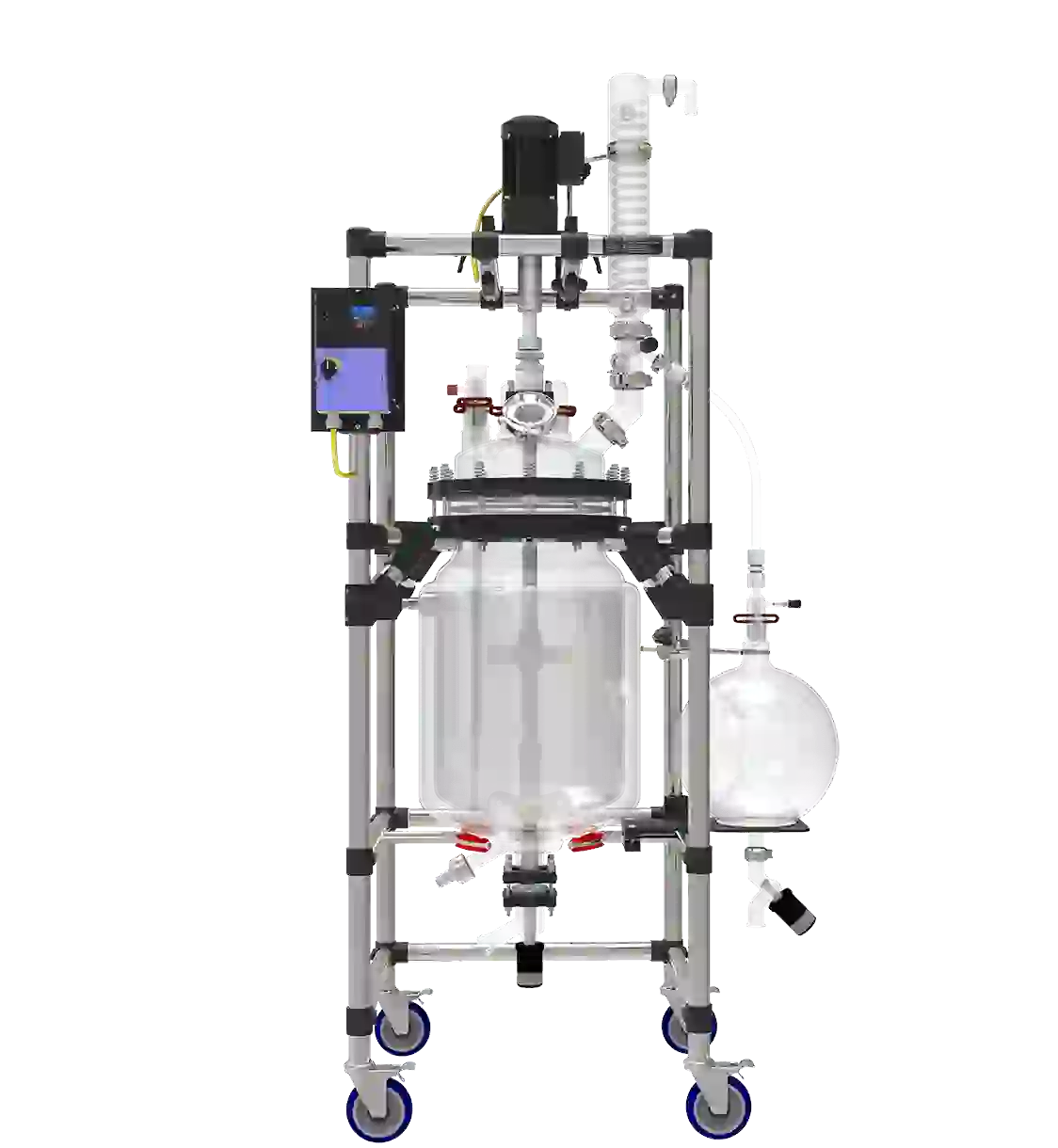

Glass reactor system

For over 90 years, H.S. Martin has been at the forefront of designing and manufacturing innovative glassware and engineered systems. Our commitment to quality and customer satisfaction has made us a trusted name in the industry, with a focus on supplying apparatus that includes stainless steel fittings for superior performance.

Among our range of cutting-edge products, our glass reactor systems stand out as versatile tools for various scientific and industrial applications. This article will provide an overview of glass reactor systems, explore their uses, features, benefits, and customization options, helping you understand why they are the right choice for your needs.

Why glass reactor systems are the right choice for you?

At H.S. Martin, we understand the importance of choosing the right equipment for your processes. Our glass reactor systems are meticulously designed and manufactured to meet the highest standards of quality and performance. Whether you’re conducting research in a laboratory setting, or scaling up production in an industrial environment, our reactor systems offer unmatched reliability and flexibility.

What is a glass reactor system?

A glass reactor system is a versatile piece of equipment used in various chemical processes. It consists of a glass vessel, typically made of borosilicate glass, which is resistant to thermal shock and chemical corrosion. The vessel is equipped with accessories such as a stirrer, temperature control system, and ports for adding reagents or sampling.

Applications of glass reactor systems

Glass reactor systems are used in a wide range of industries, including pharmaceuticals, biotechnology, petrochemicals, and academia, with customizable sizes ranging from 500ml to 200l. They are used for conducting chemical reactions, synthesis of organic compounds, crystallization, distillation, and many other processes. Their versatility makes them indispensable tools for research, development, and production.

Features and specifications

Our glass reactor systems come in various configurations to suit different requirements. Here are some key features and specifications of our products:

Jacketed Glass Reactors

- Equipped with a double-layered vessel for efficient heat transfer and temperature control

- Ideal for reactions that require precise temperature regulation

- Available in sizes ranging from 500ml to 150L to accommodate varying reaction volumes

Triple Jacketed Glass Reactors

- Equipped with a double-layered vessel for efficient heat transfer and temperature control

- The third jacket is a vacuum jacket, which prevents frost or condensation on the outside

- Creates an adiabatic area around the reactor, ensuring ambient temperatures do not affect the heating or cooling process

- Helps improve efficiency and energy savings

- Ideal for sensitive reactions requiring the utmost thermal stability

- Available in sizes ranging from 1L to 100L

Unjacketed Glass Reactors

- Suitable for processes that do not require external heating or cooling

- Compact design for space-saving operation

- Versatile and cost-effective solution for a wide range of applications

- Available in sizes ranging from 500ml to 200L

Benefits of using H.S. Martin reactor systems

- High-quality materials: Our reactors are constructed from borosilicate glass, renowned for its durability and resistance to chemical corrosion.

- Controlled temperature: Precise temperature control ensures optimal conditions for chemical reactions, leading to improved yields and product quality through the efficient use of chillers and condensers.

- Versatility: Our reactor systems can be customized with a range of accessories and options to suit specific process requirements.

- Safety: Borosilicate glass offers excellent visibility of the reaction, allowing for real-time monitoring and minimizing the risk of accidents.

- Ease of use: User-friendly design and intuitive controls make our reactor systems easy to operate and maintain.

Types of glass reactors: Jacketed vs. Unjacketed

Jacketed glass reactors are equipped with a double-layered vessel, providing efficient heat transfer and temperature control. They are ideal for processes that require precise temperature regulation, such as synthetic reactions and crystallization.

Unjacketed glass reactors, on the other hand, are more compact and cost-effective, making them suitable for a wide range of applications where external heating or cooling is not required.

High-quality material: borosilicate glass

At H.S. Martin, we use only the highest quality borosilicate glass in the construction of our reactor systems. Borosilicate glass is renowned for its exceptional durability, thermal stability, and resistance to chemical corrosion, making it the ideal choice for demanding applications in the chemical and pharmaceutical industries.

Customization options for your specific needs

We understand that every process is unique, which is why we offer a wide range of customization options for our glass reactor systems. Whether you require additional ports, specialized accessories, or custom design features, our team of experts will work with you to create a solution that meets your exact requirements.

Related equipment and accessories

In addition to our glass reactor systems, we also offer a range of related equipment and accessories to enhance your workflow:

- Vessel Replacements: Easily replaceable glass vessels for quick maintenance and minimal downtime.

- Accessories: circulators, vacuum pumps, burst discs, over-pressure valves, temperature probes, pressure transducers, pumps for feed and discharge.

Looking for custom reactors for your needs?

If you require custom reactor systems for your specific applications, look no further than H.S. Martin. Our experienced team will work closely with you to design and manufacture a solution that meets your exact specifications. Contact us today to discuss your requirements and learn more about our custom reactor options.

H.S. Martin’s glass reactor systems offer unmatched reliability, versatility, and performance for a wide range of scientific and industrial applications. With high-quality materials, customizable designs, and a commitment to customer satisfaction, our reactor systems are the right choice for your process needs.